In recent decades, the properties of high-density polyethylene (HDPE) have been significantly improved due to its high application in various industries. Therefore, strict standards have been used to evaluate its properties. Some of these performance tests may take several months, including the environmental stress cracking test. Because standard test methods for measuring plastic' ESCR1 take a long period of time (sometimes months), the quality of the products is acceptable if they do not fail.

Nowadays, the term "slow crack growth resistance" is used to describe all ESCR test methods. The most widespread and oldest method is the ESCR test of bent specimens. Due to the linitations of this method, especially the long test time, several other tests were developed, such as Notched Constant Tensile Load2 (NCTL) and PENT3 tests in the United States and FNCT4 test in Europe.

ASTM D1693- ESCR test of bent specimens

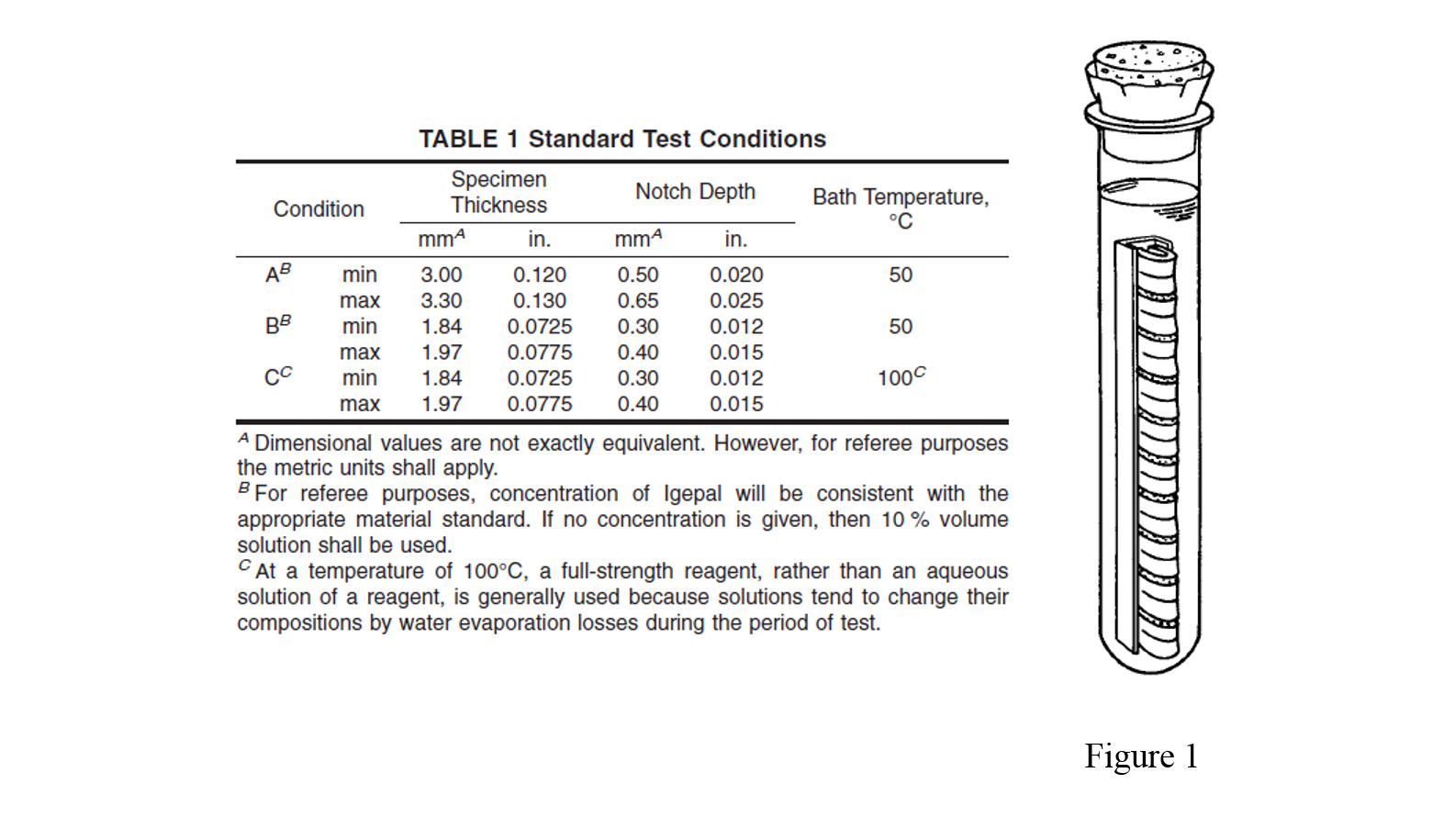

This test was first developed by Bell Labs in the late 1940s. Ten rectangular-shaped specimens are cut from a molded plaque prepared with standard methods. A controlled notch is cut horizontally across each specimen, which serves as a crack initiation point. The specimens are bent and inserted into a "C" shaped bracket, creating stress in the specimen. The schematic of this test is shown in Figure 1. The specimens and bracket are inserted into a tube filled with IGEPAL® solution. The tube is then placed into a heated environment and inspected periodically for cracking (failures). Parameters such as solution concentration, environment temperature and sample dimensions change according to the test conditions, as shown in Table 1.

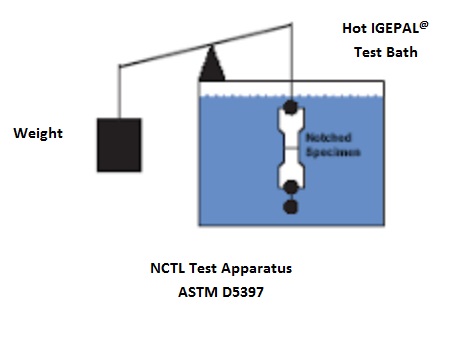

ASTM D5397- Single Point Notched Constant Tensile Load (NCTL) Test

This method is commonly used in the United States for geomembrane materials. Typical test conditions are 50 ° C in the 10% IGEPAL® solution and the applied load is 30% of sample's yield stress. The notch depth is 20% of the sample thickness. The schematic of this method is shown in following Figure. Time of failure is recorded. Test results only depend on test conditions and do not indicate relative performance at other conditions. Failures that occur in the brittle mode indicate slow crack growth performance.

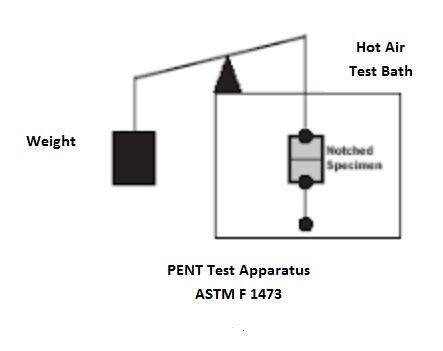

ASTM F 1473 - The Polyethylene Notch Tensile (PENT) Test

This method is used in the United States to test PE Pipe grade materials. Typical test conditions are 80°C air and 2.4 MPa stress. A diagram of this test method is shown in following Figure. Specimens are machined directly from pipe or from a molded plaque with dimensions 10 x 25 x 100 mm. A single notch cut into the test specimen acts as a crack initiation point so that notch depth is dependent on sample thickness. Side notches are made to facilitate the cracking in the main notch, and the applied load expedites the cracking mechanism, leading to sample failure.

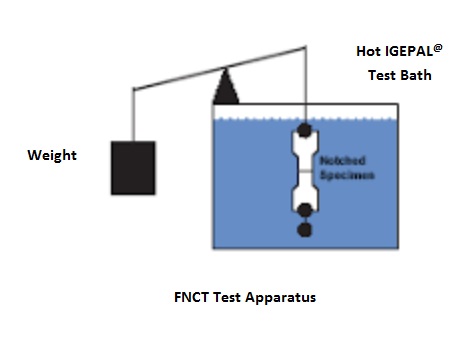

The Full Notch Creep Test (FNCT)

This method is accepted throughout Europe as the standard method to test PE Pipe grade materials exhibiting very high ESCR values. The FNCT test is preferred to the PENT test in Europe, as it leads to shorter failure times due to its particular specimen design and to the presence of a surface-active environment, such as IGEPAL®. No generally accepted test conditions have yet been established for the FNCT test, contrary to the PENT test. Nevertheless, the FNCT test is being increasingly discussed in the European PE pipe industry. This method is diagrammed in following Figure. Typical test specimens measure 10 x 10 x 100 mm and are machined directly from pipe or from a molded plaque. Specimens are notched on all four sides, ensuring that notches are coplanar, with typical notch depth of 1,500 microns. The specimen is inserted in the grips of the tensile creep machine and dipped in a temperature controlled and circulated testing bath at 80° or 95°C. Typical loads are set between 4 and 5 MPa. Time to failure is recorded for each sample.

1 Resistance Environmental Stress-Cracking

2 Notched Constant Tensile Load

3 Polyethylene Notch Tensile

4 Full Notch Creep Test